Tank Car Lined Ball Valves

AAR noncertifications – New Options/ Technologies

Can you afford to wait 12-24 months to get lined valves for your tank car fleet? Did you know there is now an additional option?

Whether building new tank car or conducting scheduled maintenance, if your cars use lined ball valves, the two major suppliers of these valves are currently non-certified with the Association of American Railroad (AAR). It could easily be 12-24 months, before these manufacturers are able to re-supply their products.

Current Options:

When transporting hazardous chemicals, the goal is to prevent those chemicals from eating through their containment either through chemical corrosion and permeation. Exotic nickel-alloy metals are unquestionably the superior option, unfortunately they expensive. For this reason, the most viable alternative is PFA lined valves.

There are three current manufacturers of AAR approved lined tank car valves. All feature ductile iron bodies, two use plug valves, the third a ball valve: -

Ductile iron bodies – which are a good option for valves, but is not as impervious or anti-corrosive as stainless steel.

PFA lined Bodies, Stems & Plug/ Balls – providing a virtually universal resistance to attack from virtually all chemicals. Similar to PTFE, it offers a broad operating temperature range but with better permeation resistance than PTFE.

Plug Valve vs Ball Valve - Plug Valves are designed to provide very accurate flow rates and are often used with actuators. Due to the small size of this aperture, their flow rates are exponentially less compared to ball valves.

New Options/ Technologies:

Fort Vale (UK), has long been the industry leader in new transportation technologies. They saw a need for a new type of lined valve that met the industries needs and have provided two options.

Unlike the existing offerings of lined valves, these valves are designed and manufactured for long-term service. They tested to withstand higher pressures, temperatures and are fully repairable.

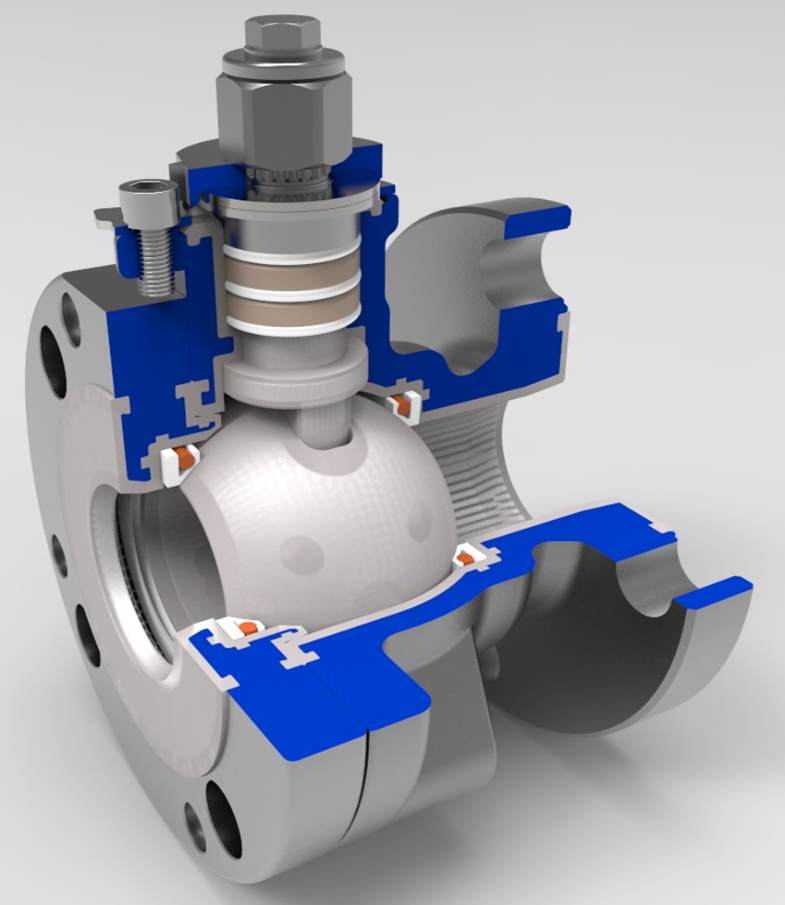

Fort Vale, has introduced a stainless steel PFA lined ball valve that is currently undergoing service trial. It is available in a 2” & 3” it comes with a choice of either Zirconium ball/ stem or a PVDF (Kynar) lined ball/ stem.

Zirconium (premium option) is comparable to other rare, non-alloy metals (Titanium & Tantalum), it offers a cost and operationally effective solution, especially when used with hydrochloric acids.

PVDF/ Kynar (competitive option) is the most commonly used of all fluoropolymers. It has excellent chemical resistance, tolerating temperatures up to 300°F (depending on the chemical service). It is a good choice for strong acids, solvents, but not recommended for caustics.

Other Features: -

100% Stainless Steel Construction

Exponentially higher flow rates

Lower profile to ensure universal fit

Reinforced/ strengthened stems to mitigate any twisting torque concerns

Live loaded / No stem adjustment required

Weep/ Inspection Ports

Comparative differences: Competition vs Fort Vale

Conclusion

Ignoring the lack of AAR approved lined valves, Fort Vale is the first lined valve specifically designed for tank cars. All the others have been adapted from other applications to fit. Fort Vale’s valve is the only lined valve that fully meets the BOE’s #150 requirements. It is designed to offer a sturdier, easier to use/ maintain option. There is no need to paint the bodies, there are no issues with corroding body bolts. Regardless of commodity, these valves represent an alternative to Hastelloy and Monel bodied valves where constant corrosion is an issue.

If you’d like more information – please contact your TransQuip (https://www.transquip.com/contact)